Choosing the Right Manufacturing Model and Process for Bedding Brands

In the competitive landscape of home textiles, selecting between OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) is a strategic decision that dictates a brand’s scalability, profit margins, and market identity. For bedding products—ranging from high-thread-count Egyptian Cotton sheets to complex Jacquard duvet covers—the choice hinges on whether a brand possesses proprietary designs or seeks to utilize factory-developed solutions for rapid market entry. This article provides an in-depth analysis of the core differences between these two models and breaks down VANY’s standard service workflows to help brands navigate the global supply chain effectively.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) | Core Advantage |

|---|---|---|---|

| Design Authority | Brand provides full Tech Pack | Factory provides design catalog | Exclusivity vs. Convenience |

| Production Flow | Includes fabric weaving & dye development | Based on stock fabric or existing patterns | High Customization vs. Quick Response |

| Lead Time | 90-120 Days (Includes R&D) | 30-60 Days (Processing Stock) | Seasonal Planning vs. Rapid Restocking |

| MOQ | High (Limited by Dye Lot capacity) | Low (Fabric sharing, high flexibility) | Cost Optimization vs. Low Risk |

Defining OEM in Bedding: Total Specification Control

OEM represents the traditional manufacturing relationship where the client dictates every aspect of the product. In the context of bedding, this means the brand provides the “Tech Pack”—a detailed blueprint specifying the yarn type (e.g., 80S Long-Staple Cotton), the weave structure (e.g., 4-over-1 Sateen), the exact Pantone color codes for dyeing, and the dimensional tolerances for pillowcases and fitted sheets.

Under this model, the bedding manufacturer functions solely as the production facility. They do not contribute to the creative design but are responsible for executing the client’s vision with precision. This is the preferred route for luxury brands and established retailers who need to differentiate their products through unique textures, proprietary prints, or specific performance features like “cooling technology” embedded in the fiber.

VANY OEM Standard Process: From Concept to Delivery

The OEM process is highly collaborative, requiring precise communication between the brand and the factory. Based on VANY’s service standards, a typical OEM workflow consists of six key stages:

1. Inquiry & Spec Confirmation

The client submits a detailed product specification sheet (Tech Pack), including fabric composition (e.g., 100% Mulberry Silk), thread count, size charts, packaging requirements, and target quantity. The VANY team evaluates technical feasibility and provides professional recommendations.

2. Costing & Quotation

Based on raw material market prices, labor costs, and process complexity, the factory provides a detailed FOB or DDP quotation. Payment terms and estimated delivery dates are confirmed at this stage.

3. Prototyping & Sampling

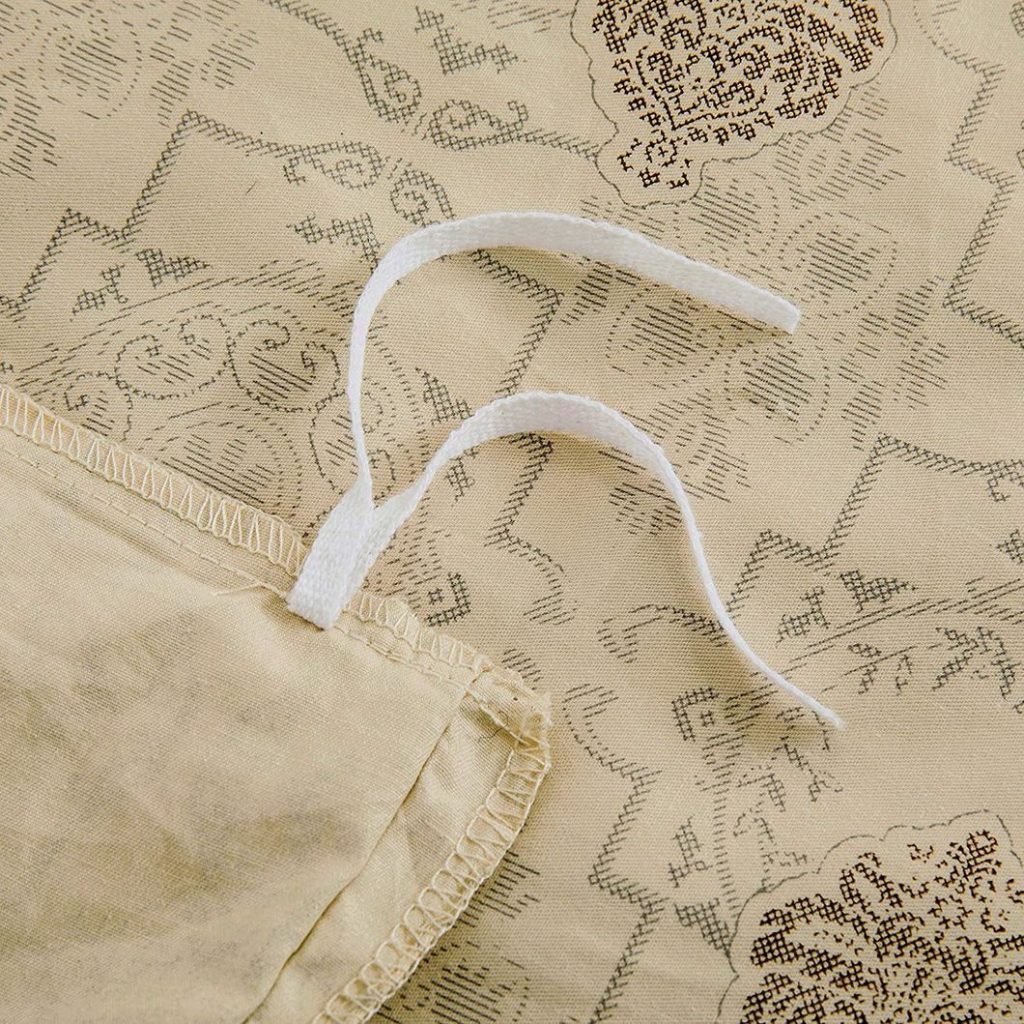

This is the most critical step. The factory produces Pre-production Samples, including “Lab Dips” for color confirmation and “Hand-feel Samples” for material verification. The sample signed and approved by the client becomes the “Golden Sample,” serving as the sole acceptance standard for mass production.

4. Material Sourcing & Production

The factory orders yarn for weaving and dyeing. Since OEM orders typically involve custom fabric production, this phase takes the longest. The process then moves to cutting, sewing, and ironing.

5. QC & Inspection

Mid-term inspections (Inline Inspection) are conducted during production, followed by a Final Inspection upon completion. Clients may appoint third-party agencies (such as SGS or Intertek) to inspect goods according to AQL 2.5 standards.

6. Packaging & Logistics

Products are exquisitely packed according to brand requirements (e.g., gift boxes, ribbons) and arranged for sea or air freight to the client’s designated warehouse.

Defining ODM in Home Textiles: The Private Label Advantage

ODM, often referred to as “Private Labeling” or “White Labeling,” occurs when the manufacturer acts as both the designer and the producer. Factories like VANY invest in their own R&D teams to create seasonal collections of duvet covers, blankets, and sheet sets based on current market trends. They develop the patterns, select the fabrics, and create the finished samples.

Clients browse a catalog of pre-developed products and select items to brand with their own logo and packaging. This model significantly lowers the barrier to entry for new brands, influencers, or e-commerce sellers who may lack a design background. It allows for “shelf-ready” products without the lengthy process of prototyping and fabric testing.

VANY ODM Standard Process: The Fast-Track to Market

The ODM process aims to shorten Time-to-Market, centering on leveraging the factory’s existing resources. The workflow is much more streamlined:

1. Selection from Catalog

Clients select styles from VANY’s existing product library, such as the currently trending “Washed Cotton 4-Piece Set” or “Geometric Jacquard Throws.” The factory provides ready-made fabric color cards for selection.

2. Private Labeling Customization

While the product structure is fixed, clients can customize branding elements. This includes Care Labels, Hangtags, Insert Cards, and outer packaging Logos. This gives standardized products a distinct brand identity.

3. Sample Confirmation

The factory sends a final sample featuring the client’s logo. Since stock fabric is used, the sample production time is extremely short (typically 3-7 days).

4. Rapid Production

Upon order confirmation, the factory immediately utilizes stock fabric for cutting and sewing. Eliminating the lengthy weaving and dyeing cycles significantly boosts production efficiency.

5. QC & Shipping

The factory’s internal standard QC process is executed to ensure defect-free products, followed by immediate arrangement for shipment.

Intellectual Property: Who Owns Your Floral Print?

One of the most critical distinctions lies in Intellectual Property (IP) rights. In an OEM arrangement, the brand retains full ownership of the designs. If a brand commissions a unique hand-drawn botanical illustration for a duvet cover, the factory cannot legally sell that design to another client. The molds, screens, and embroidery files belong to the brand.

Conversely, in an ODM arrangement, the factory retains the IP. If a client selects a geometric pattern from the factory’s library, the factory reserves the right to sell that same pattern to other retailers in different markets (unless an exclusivity agreement is signed). Brands relying on ODM must accept that their product is not entirely unique in the global marketplace.

Cost Structure: R&D Investment vs. Unit Price

The financial implications differ significantly. OEM requires upfront investment from the brand. The client pays for sample development, lab dips, and potentially the setup costs for rotary screens or digital printing files. However, because the brand invests in development, the per-unit manufacturing cost is often negotiated down, yielding better margins at scale.

ODM eliminates these upfront R&D costs. The factory has already amortized the development expenses across multiple clients. Consequently, the per-unit price for ODM products is typically higher to cover the factory’s design and inventory risks. For startups, the lower initial capital requirement of ODM is often more attractive, while mature brands prefer the margin control of OEM.

Time to Market: Custom Weaving vs. Ready-Made Stock

Speed is a major differentiator. OEM production is a slow process. It often starts with spinning the yarn and weaving the “greige” fabric, which can take 30-45 days before dyeing even begins. The entire cycle from concept to shipment can range from 90 to 120 days. It is a model built for planned seasonal drops, not reactive trends.

ODM offers agility. Manufacturers typically hold stock of popular fabrics (like standard 300TC cotton or microfiber) and have designs ready for immediate printing or cutting. An ODM order might only require sewing and packaging, reducing the lead time to 30-45 days. This allows brands to capitalize on sudden trends, such as a spike in demand for “Teddy Fleece” blankets during a cold snap.

MOQ Dynamics: The Reality of Fabric Consumption

Textile manufacturing is governed by fabric dyeing machines, which have minimum capacity requirements. For OEM orders requiring a custom Pantone color or a specific weave, the MOQ is dictated by the minimum dye lot—often 3,000 meters per color. This translates to roughly 1,000 sheet sets or duvet covers.

ODM bypasses this hurdle by aggregating demand or using stock fabric. Since the factory uses the same white Tencel™ Lyocell fabric for five different clients, they can offer much lower MOQs to each individual brand—sometimes as low as 100 or 200 units. This flexibility is crucial for testing new markets without committing to heavy inventory.

Quality Control Responsibilities in Different Models

In an OEM partnership, the brand typically sets the AQL (Acceptable Quality Limit) standards and often hires third-party inspectors to verify the goods before shipment. The brand is deeply involved in quality assurance because the product specs are their own.

In ODM, the brand relies more heavily on the factory’s internal QC processes. Since the product is the factory’s standard output, the factory guarantees that it meets their own baseline quality. Brands must vet ODM partners carefully to ensure their definition of “quality” aligns with the factory’s output.

VANY’s Hybrid Approach: Flexible Solutions for Growth

The binary choice between OEM and ODM is evolving. VANY offers a hybrid solution that caters to diverse business needs. We maintain a library of ODM designs for rapid deployment while possessing the technical infrastructure for full-scale OEM production. This allows a brand to launch quickly with an ODM collection (e.g., a core line of solid bamboo sheets) while simultaneously developing a custom OEM flagship product (e.g., a signature Jacquard collection) for future release.